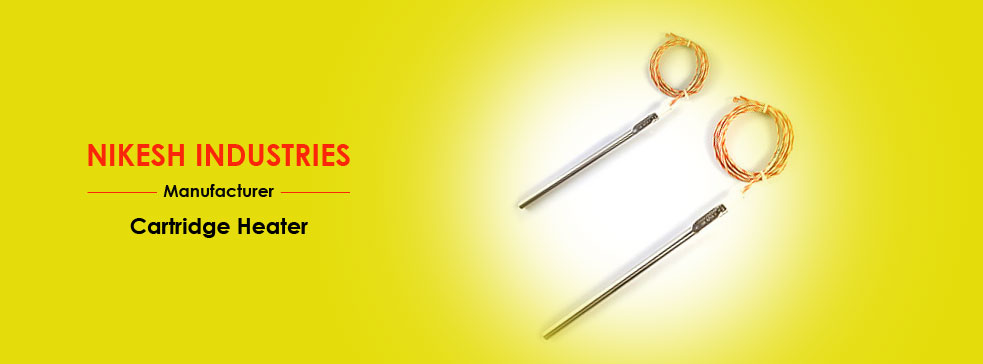

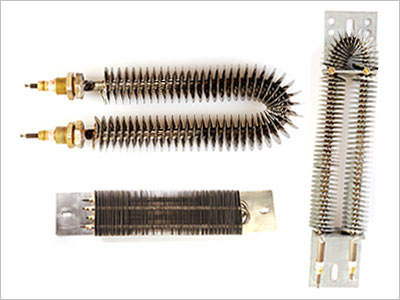

Straight type Cartridge Heater available in low, medium and high watt density. Helically wound Nichrome 80/20 Resistance coils fitted in steatite ceramic insulators and insulated by high purity MGO. Outer sheath SS304, SS306, Brass with suitable connection.

Features:

Terminals are at one end with Fiber Glass / Teflon Coated / Silicon Coated / Ceramic Insulator wire or stud type terminals. Heater dia from 5mm to 100mm, length as per requirement. Wattage/voltage as per requirement.

Application:

Molding dies, Plastic Processing machinery, Injection and Blow, Molding Machinery, Extruder , Rubber Molding, Foundries, Packaging Machinery, etc.

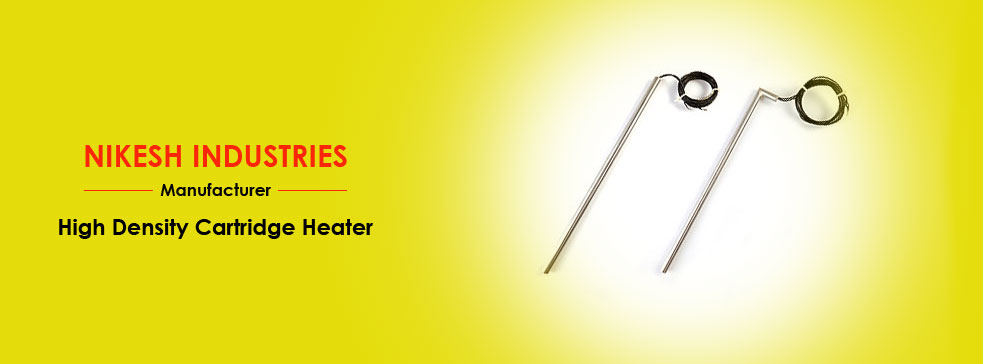

High - Density cartridge heaters are among the most versatile and widely used cartridge heaters throughout the industry. They are valuable for alleviating problems created by high watt densities, high wattage, excessive vibration, poor fit, or where short heater life is a constant problem.

Features:

Designed for High watt density, the use of high purity MgO insulation assures high dielectric strength fast heat transfer efficiency, swaging increases the high thermal conductivity and uniform heating Shock and vibration resistant, Available also with built in thermocouple, they are economical & versatile A full range of sizes are readily available from stock.

Application:

Widely used to heat the plastic injection molds, various packeging industries, dies, hot plates, platens and many more applications.

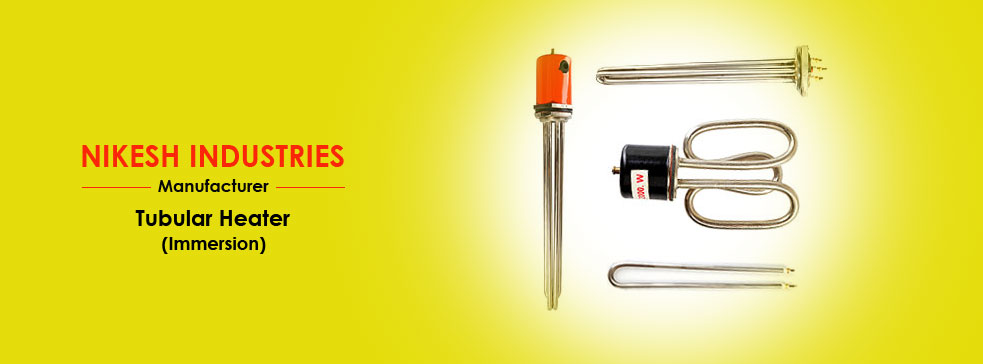

Made out of Nichrome 80 / 20 / Kanthal DSD wire, "A" Grade magnesium oxide & high quality tubing. Filling machines and swaging equipment's maintain tolerances. Metal sheaths includes SS304, SS316, Incoloy 800.

Features:

Tubular Heaters (Air Immersions) are mineral insulated, metal - sheathed electric resistance heater. It can be available in various Dia, size and shapes as per requirements like water immersion, oil immersion heaters, alkaline heater, "U" / "W" bend heaters, Finned Air Heater, Straight heater, etc.

Application:

Oven, Dryers, Packaging Machineries, Plastic Processing Industries, Vacuum Forming Machines, Hatcheries, Corrugation Machines, Chemical, Oil Filtration, Foundries, Automobile, Pharmaceuticals, Hotels, Winery, Glass Industries ,etc.

The heating coil is placed inside of the quartz tube. If the element is operating vertically or at an angel, the coil should be tight-wound and pre - oxidized. For Horizontal use the relative pitch is 1.2-2.0 Ceramic long wave infra red heaters available in flat, trough and hollow styles. Made of cast-in iron chrome aluminum resistance wire heating elements.

Features:

It gives Non-contact heating , one stage transfer, faster rate of heating , low thermal inertia, emitters that respond instantly, no combustion by product, modular construction.

Application:

Space Heating, Toaster Ovens, Grills, Industrial infrared dryers, Paint baking, Paper coating drying, Screen printing curing, Glass & ceramic drying and sterilizing, Glass bending and annealing, Mirror coating, Powder coat curing vacuum forming, Poly film industries, Electronics PCB industries, etc.

Made out of Nichrome 80/20 wire, "A" Grade magnesium oxide and Non compacted hot rod ceramic insulators. Metal sheath includes SS304, SS316, Titanium, etc. And also in silica glass tubes.

Features:

Easily mounted on all types of immersion tank. It can be mounted vertical and horizontal. It allows you max. Watt density. It has been provided that its performance is excellent than traditional tubular heaters.

Application:

Salt tempering furnaces, Acid regeneration plant (ARP), Chemical plant, Oil filtration, Automobile industries, Industrial washing machines, Powder coating and plating plants, etc.

Made out of special ceramic 'Steatite' with high thermal conductivity along-with helically wound Nichrome 80/20 resistance coil.

Features:

Panel heaters are easy to control. It has wider range of wattages. It is easy and economical install.

Application:

Ovens and cabinet warming for drying, melting, baking, Moisture protection in motors, Control cabinets, Load resistors, Clamped on to platens, Tank, Hot plates, Dies, Moulds, Tin Melting, Weld pre heating.

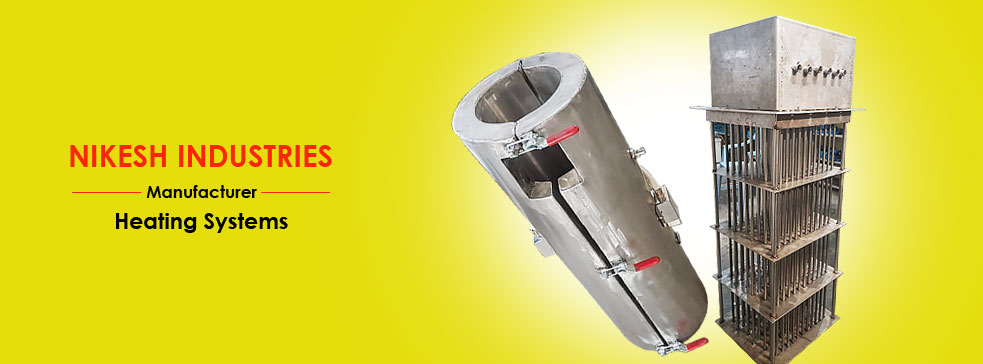

Heating elements made out of Nichrome 80/20 Kanthal A1, Kanthal AF, Kanthal DSD, Incoloy 600 in wire, strips and rods different shapes as per specification.

Features:

It is available in spiral and strip in grooves, rod over bend element, corrugated strip or wire element, bird-cage element (hair pin type). Temperature range 300-1300 degree Celsius.

Application:

All type of furnaces and ovens.